The basics of FDM printing technology

What is FDM printing and how does it work?

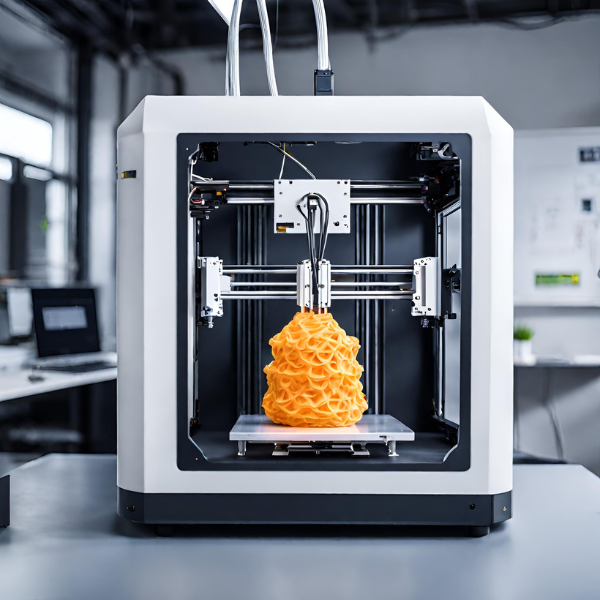

FDM printing, or fused deposition modeling, is a 3D printing method. A plastic filament is melted. It is applied layer by layer to a construction platform. The object is created layer by layer. A computer-controlled print head moves precisely to do this. This is how three-dimensional objects are created from the filament. This is a popular process among do-it-yourselfers and professionals.

Advantages and disadvantages of FDM printers

fdm printers are widespread and popular. However, they have both advantages and disadvantages. The advantages include low cost, ease of use and a wide range of materials. However, there are also disadvantages. These include an often lower resolution compared to other printing technologies. Additionally, overhangs and fine details can be challenging. Nevertheless, FDM printers offer a solid solution for many projects.

Comparison between FDM and other 3D printing technologies

Compared to other 3D printing technologies, FDM has its special features. It is often cheaper and easier to use than SLA (Stereolithography) or SLS (Selective Laser Sintering). FDM requires fewer special environments and materials. But it also has disadvantages. The surface texture is often rougher. Details are also less fine than with SLA or SLS. In industry, FDM is used for prototypes or simple parts. SLA and SLS are for more complex, fine parts. However, FDM technology is evolving. It becomes more precise and versatile for different materials. A comparison is important in order to choose the right technology for your project.

Expert tips for optimizing your FDM printer

Material selection and its effects on printing

- Choose the right material for your project.

- Different materials influence strength and flexibility.

- Consider the temperature resistance of the filaments.

- Check compatibility with your FDM printer.

- Pay attention to the moisture sensitivity of the materials.

- Consider how the choice of material influences post-processing.

- Consider using specialty filaments for specific needs.

Improve print quality through optimized slicing settings

Slicing software is crucial for good printing results. Here are a few tips for optimization:

- Choose the right layer thickness for your object. Thinner layers mean finer details but take more time.

- Adjust the infill density. Higher infill makes parts more stable, but increases material and printing time.

- Find optimal print speed. Faster is not always better. Too fast can lead to mistakes.

- Use support structures cleverly. They help with overhanging parts, but should be easy to remove.

- Align the print bed and check the temperature. A level bed and correct temperature prevent warping.

With these settings your fdm printer will deliver optimal results. Try it!

Maintenance and care of your FDM printer for longevity

Good maintenance is crucial to extending the life of your fdm printer. Here are some tips:

- Clean the print nozzle regularly to avoid blockages.

- Check all moving parts for wear and lubricate if necessary.

- Keep the print plate clean and ensure it is always properly aligned.

- Update your printer's firmware to benefit from improvements and fixes.

- Store your filaments correctly to avoid moisture and dust that can cause printing problems.

Regular care and maintenance can improve print quality and reduce downtime.

Advanced applications and projects

Advanced techniques for complex print jobs

Mastering advanced techniques is crucial for complex 3D printing jobs. Here are some methods that professionals can use:

- Dual Extrusion allows printing with two materials or colors. This is how detailed models are created.

- Optimize support structures helps print overhangs and complicated geometries.

- Adjust variable layer heights to save time and improve surface quality.

- Post-processing techniques such as sanding and painting refine the printed object.

- Temperature management in the printer for stable printing results.

Using these techniques requires experience and a willingness to experiment. They take FDM printing to a new level.

Integration of FDM printing into professional workflow systems

fdm printers play a major role in professional workflows. Here they are often central to rapid prototyping. Companies use FDM printing to create models quickly and cost-effectively. They can be integrated into many systems. CAD software is used to design models. These are then sent directly to the printer. Integration is important for smooth processes. This is how prototypes are created without long waiting times. It is also possible to integrate FDM into production lines. This allows the production of end products in small batches.

Future-oriented developments in the FDM printing area

The world of FDM printing is evolving quickly. New materials and techniques are pushing the boundaries of what is possible. Improvements in software and hardware result in finer details and stronger parts. Smart printers with better networking make integration into industries easier. In addition, sustainability concepts are becoming more important. This is promoted through the use of biodegradable filaments and recycling systems. FDM technology is on the way to becoming a main means of production.